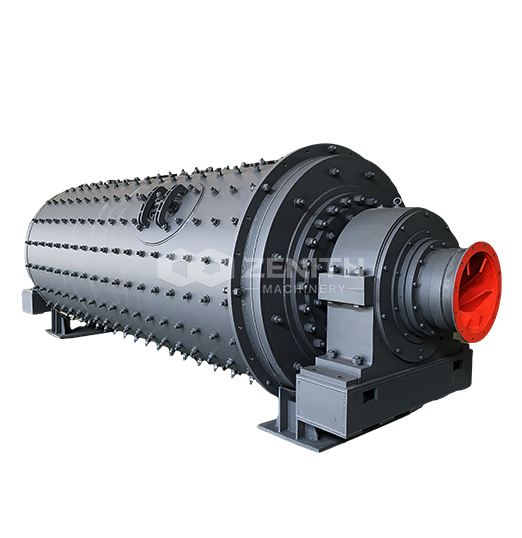

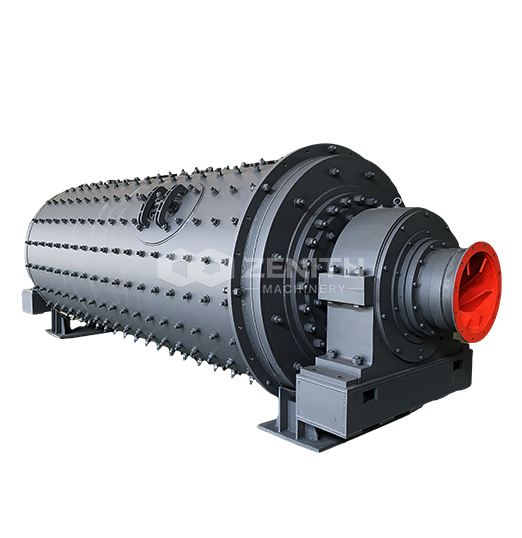

Ball Mill

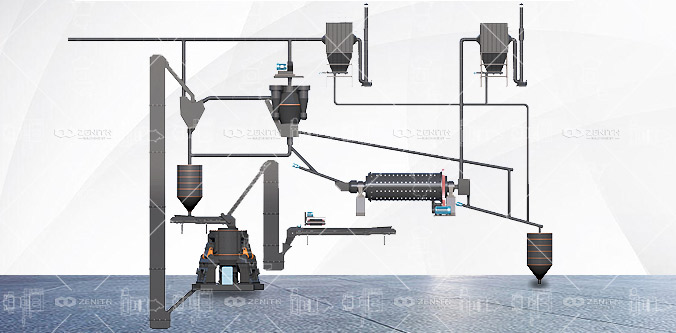

Ball Mills are mainly used in metallurgy, chemical industry, electric power, cement and other industrial and mining business to make all kinds of ores and other grindable materials by virtue of such characteristics as strong adaptability to raw materials, excellence in continuous production, high crushing ratio and easy to adjust the fineness of the finished product. An open or closed system can be set as required according to the production model, the dry and wet process production can be adopted or the grinding and drying operations can be completed at the same time.

The grinding ratio of ball mill can reach more than 300, and it is easy to adjust the fineness of the final products.

Ball mill has strong adaptability to raw materials and high production capacity, and it can meet the requirements of most of the raw materials.

This ball mill can be used in dry grinding and wet grinding.

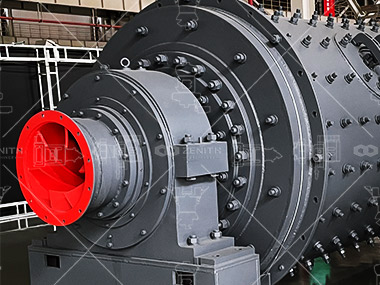

The hollow shaft in the mill is made of steel casting. The liner is detachable and wear-resistant.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.