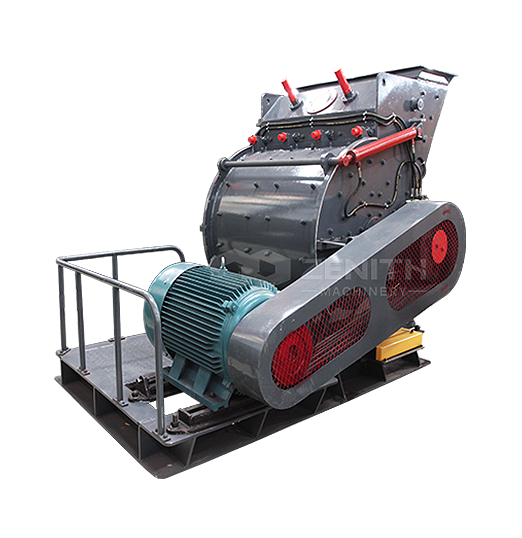

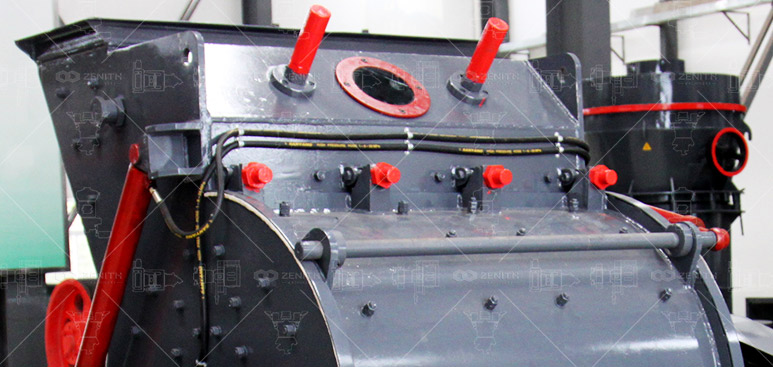

Hammer Mill

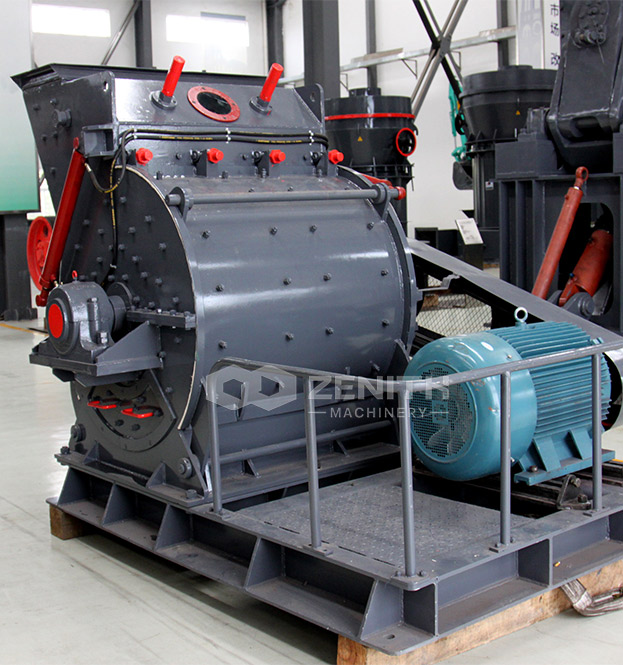

HM series hammer mills are a new generation of grinding equipment for producing 0-3mm coarse powder. This mill adopts a partial working priciple of crushers and makes up the disadvantage of uneven particle size of finished products in traditional coarse powder mills. Now, it has become the core equipment for production of coarse powder particles, which are widely used in dry mortar, animal feed, agriculture, construction material, etc.

Hammer Mill has the advantages of good grinding performance. It has higher output and grinding ratio.

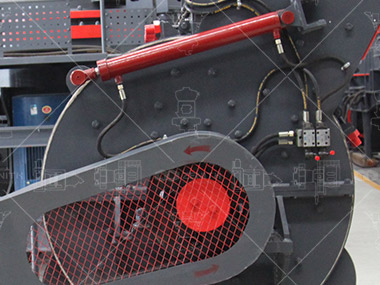

Hammer Mill has optimized cavity design and unique operating principle. The performance of this mill is excellent and stable.

Hammer Mill has high cost-effective, simple working process. It takes only a little space, saving costs for foundation base.

The casing with high manganese steel lining has higher abrasion resistance and longer service life.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.