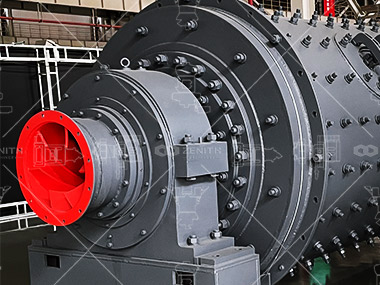

Mining Ball Mill

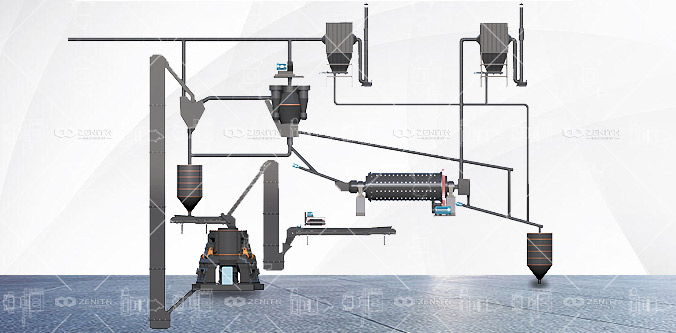

Mining ball mill is an efficient, energy-saving, and durable mining equipment widely used in multiple industries. Mining ball mills are mainly used for grinding materials in industries such as refractory materials, cement, fertilizers, glass, mineral processing, ceramics, and chemical engineering. In the preparation of aerated concrete raw materials, ball mill is also one of the most important equipment. It is suitable for grinding materials such as lime, gypsum, sand, slag, etc. These materials can only be fully mixed after being ground and reaching the required fineness, so as to achieve the strength of the product.

The ball mill has efficient grinding ability, providing high-quality raw materials for processing technology.

Modern ball mills adopt advanced transmission technology and energy-saving design, which can significantly reduce energy consumption.

Ball mills are suitable for various types of ores and mineral processing processes.

The structure of the ball mill is simple, easy to operate and maintain, and the equipment runs smoothly and reliably.

Fill your requirements here, and we'll send the custmized solution and quotation to you by the reserved contact information.