Annual 200 Kilotons Limestone Powder Grinding Project

Material: limestone

Input Size: <45mm

Output Size: 150-200mesh

Application: mine filling

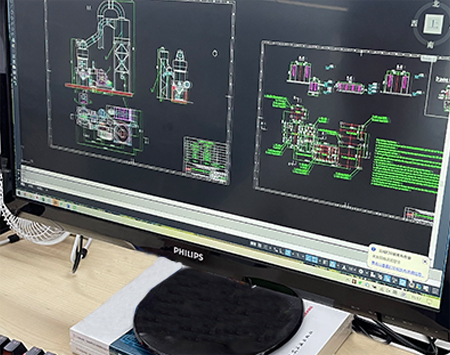

Equipment: ZENITH LM vertical roller mill

The limestone powder preparation production line of the enterprise adopts ZENITH's patented product - LM vertical roller mill. The entire production line has a reasonable process layout, stable equipment operation, environmentally friendly and efficient production, and the fineness of the finished product meets the standard. The output meets customer expectations!

![[list:title]](/static/upload/image/20250113/1736750105151666.jpg)

![[list:title]](/static/upload/image/20250113/1736748312606610.jpg)

![[list:title]](/static/upload/image/20250113/1736746518206581.jpg)

![[list:title]](/static/upload/image/20250113/1736736872183986.jpg)