16 t/h Quicklime Powder Making Project

Material: quicklime

Feed Size: <40mm

Output Size: 80-100mesh

Capacity: 16 t/h

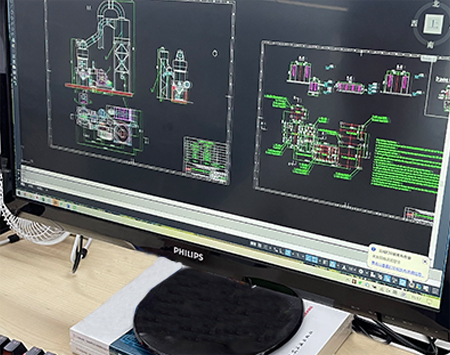

Equipment: 2 sets MTW138 Series European Mill

The customer purchased two MTW138 European grinding mills from Zenith a few years ago, mainly used to process quicklime for desulfurization in steel plants. Since it was put into operation in 2017, the equipment has been running stably, and the grinding rollers and grinding rings have never been replaced. The customer is very satisfied.

![[list:title]](/static/upload/image/20250113/1736750105151666.jpg)

![[list:title]](/static/upload/image/20250113/1736748312606610.jpg)

![[list:title]](/static/upload/image/20250113/1736746518206581.jpg)

![[list:title]](/static/upload/image/20250113/1736736872183986.jpg)